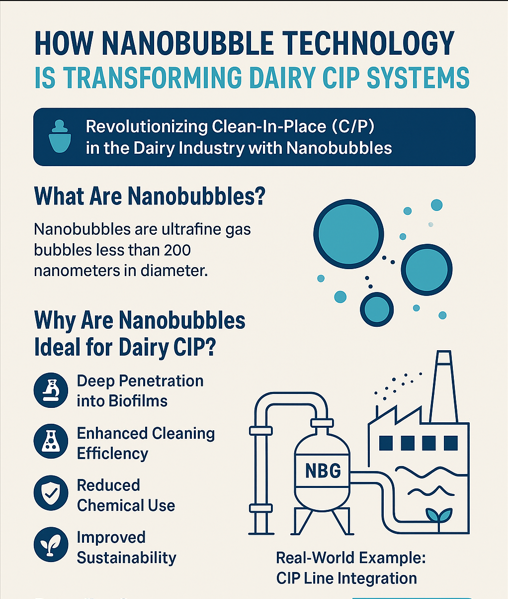

🧼🥛 Revolutionizing Clean-in-Place (CIP) in the Dairy Industry with Nanobubbles

The dairy industry is one of the most hygiene-sensitive sectors, where equipment cleanliness directly affects product quality, safety, and shelf life. Traditional Clean-in-Place (CIP) systems rely heavily on water, chemicals, heat, and time to clean pipelines, tanks, and other equipment—leading to high operational costs and environmental concerns.

But what if there was a smarter, greener way to clean?

Enter nanobubble technology—a cutting-edge innovation that’s changing the game in CIP processes across dairy operations.

What Are Nanobubbles?

Nanobubbles are ultrafine gas bubbles less than 200 nanometers in diameter—about 2,500 times smaller than a grain of salt. Unlike regular bubbles, they:

- Remain stable in liquids for long periods

- Generate strong oxidative power

- Improve gas solubility (like oxygen or ozone)

- Create shockwaves during collapse to remove contaminants

These properties make nanobubbles powerful cleaning agents—without the need for excessive chemicals or heat.

🧪 Why Are Nanobubbles Ideal for Dairy CIP?

Dairy processing equipment is prone to stubborn residues like:

- Protein and fat buildup

- Biofilm formation from bacteria

- Mineral scaling (e.g., calcium deposits)

Traditional cleaning requires multiple steps: pre-rinse, caustic wash, acid wash, sanitization, and rinses in between—all consuming water, energy, and chemicals.

Nanobubble technology enhances or even replaces parts of this process by:

✅ 1. Deep Penetration into Biofilms

Nanobubbles reach into microscopic crevices and disrupt biofilm matrices, which conventional chemicals often fail to remove completely.

✅ 2. Enhanced Cleaning Efficiency

When infused with gases like oxygen or ozone, nanobubbles generate reactive oxygen species (ROS) that break down organic matter more effectively.

✅ 3. Reduced Chemical Use

Nanobubbles can reduce the need for strong caustic or acid chemicals—making the CIP process greener and safer.

✅ 4. Improved Sustainability

Less chemical usage + lower water consumption + shorter cleaning cycles = a more eco-friendly dairy operation.

🏭 Real-World Example: CIP Line Integration

Imagine a dairy plant’s pipeline system retrofitted with a Nanobubble Generator (NBG) inline with its rinse water line. When cleaning begins:

- Water + nanobubbles flow through the system

- Bubbles penetrate residues and biofilms

- Proteins and fats are loosened without excessive detergents

- Shorter rinsing needed post-chemical wash (if used)

- The result: Clean equipment, lower costs, higher hygiene

| Benefit | Traditional CIP | CIP with Nanobubbles |

|---|---|---|

| Water consumption | High | Reduced by 20–30% |

| Chemical usage | High | Reduced by 40–80% |

| Cleaning time | Long cycles | Shorter, more effective |

| Biofilm removal | Incomplete | Deeper penetration |

| Environmental footprint | High | Significantly lower |

🌱 Moving Toward a Chemical-Free Future

Some dairy innovators are exploring chemical-free or low-chemical CIP cycles using nanobubbles alone or in combination with ozone, electrolyzed water, or UV. With increasing pressure to reduce chemical residues in food production, nanobubbles offer a promising path forward.

🧭 Conclusion: Small Bubbles, Big Impact

Nanobubble technology brings precision, efficiency, and sustainability to dairy cleaning operations. Whether you’re managing a large dairy plant or looking for new ways to optimize cleaning protocols, nanobubbles can cut costs, improve hygiene, and protect the environment.